Cutting

Serkon Makina is a trusted name in textile machinery, known for delivering innovative, high-precision equipment tailored to the evolving needs of the global textile industry. With decades of engineering expertise and a strong focus on automation, efficiency, and durability, Serkon’s machines are built to support scalable, high-quality production.

For textile manufacturing businesses aiming to optimize throughput, reduce waste, and maintain consistent output, Serkon machinery—such as the flagship DC-90 model—offers a smart, future-ready solution. Integrating Serkon equipment into our production line has allowed us to enhance fabric processing efficiency, improve cutting accuracy, and meet increased production demands with confidence.

Single Solution for Mass Production

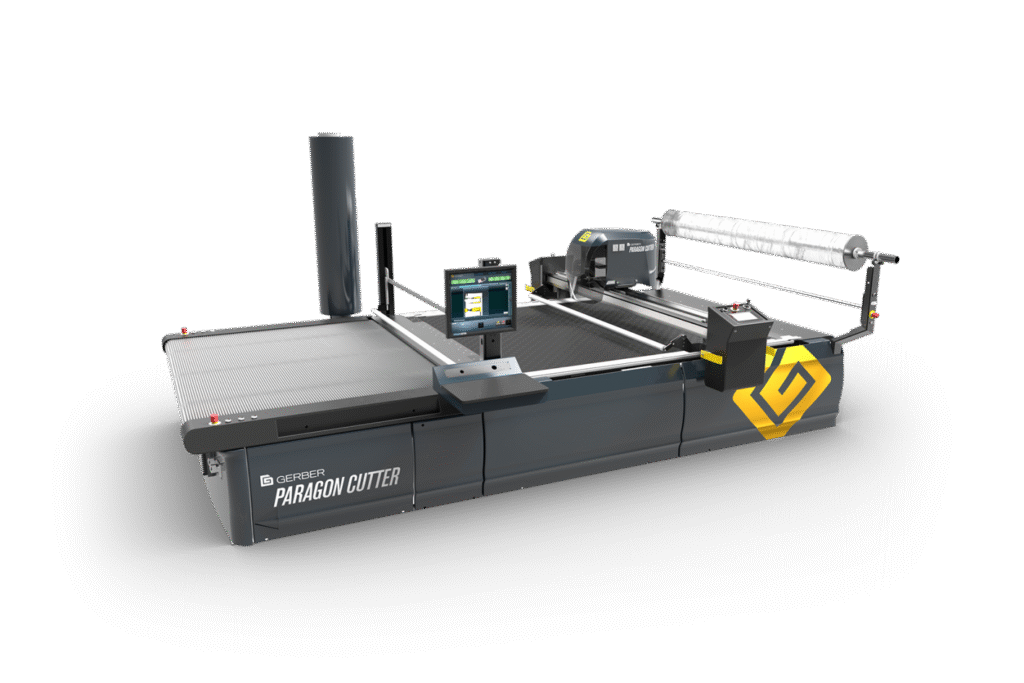

In today’s fast-paced fashion industry, speed, precision, and adaptability are essential. Formerly known as Gerber cutters, Lectra’s advanced fabric cutting solutions are trusted by fashion brands and manufacturers around the world to bring collections to life—faster, smarter, and at scale.

From initial samples to full-scale production runs, Lectra technology enables fashion teams to automate the cutting process with exceptional accuracy, reduce fabric waste, and accelerate time-to-market. Whether you’re managing in-house production or scaling across multiple facilities, we utilize Lectra to keep pace with demand without sacrificing quality or creativity.

Seamlessly integrated with digital pattern-making and production workflows, Lectra cutters are built for the future of fashion—where data-driven design meets agile manufacturing.

Precision Mass Cutting

Specialized Garment Cutting

Our garment mass cutting services are designed to support brands and manufacturers with high-precision, large-scale fabric cutting. Utilizing advanced cutting technology and expert technicians, we ensure every piece is cut to exact specifications, minimizing waste and maximizing fabric efficiency.

We work with a wide range of fabrics, from delicate materials to heavy-duty textiles, and can handle both small and large production volumes. Beyond standard cutting, we also offer marker making, fabric spreading, and quality control to ensure each layer and cut is perfectly aligned and production-ready.

Whether you’re preparing for in-house manufacturing or third-party assembly, our cutting services provide the reliability and scalability your business needs.

FAQ

What exactly are cutting services?

Cutting services involve laying out fabric and cutting garment pieces based on your approved patterns and markers. This is a critical step that ensures each piece is precise, consistent, and ready for sewing.

Who is this service for?

We work with brands, designers, and manufacturers who need professional, high-volume cutting for production — whether they sew in-house or with another facility.

Do you offer just cutting, or also sewing?

We offer both, but our cutting services can be booked as a standalone service. Many clients who sew elsewhere still rely on us for accurate, efficient cutting.

What’s the minimum and maximum cutting volume you handle?

Our minimum is 100 units per style, but we’re set up to handle up to thousands of units per order. We can scale depending on your needs.

What materials can you cut?

We cut a wide range of fabrics including:

- Wovens (cotton, linen, denim)

- Knits (jersey, rib, interlock)

- Performance fabrics

- Stretch and delicate materials

If your fabric is unusual or specialty (e.g., leather, coated fabrics), just let us know in advance.

Do I need to provide patterns and markers?

Yes, ideally. We require final, approved patterns and graded sizes. If you don’t have markers, we can create them for you (at an additional cost), based on your fabric width and size breakdown.

Can you help with marker making and fabric optimization?

Yes! We offer marker making services to help you maximize fabric yield and reduce waste. Our team uses CAD systems to ensure precise layout and efficient fabric use.

What is a lay plan, and do you provide it?

A lay plan (or marker) is the digital blueprint for how your patterns are placed on fabric before cutting. We can generate it for you if needed, especially if you’re trying to reduce fabric consumption.

How accurate is your cutting process?

We use industrial cutting machines and trained professionals to maintain consistency across layers. Tolerances are minimal, and every batch is checked for alignment and accuracy.

Can you handle bulk cutting for stretch or slippery fabrics?

Yes. For challenging fabrics (like lycra, silk, chiffon), we take extra steps such as tension control, paper layering, and specialized blades to ensure clean and accurate cuts.

How long does the cutting process take?

Lead time depends on volume, number of styles, and fabric type — but generally, we can turn around cutting within 3 to 7 business days once we have everything needed (fabric, markers, approvals).

What do I need to provide for the cutting service?

You’ll need to supply:

- Finalized & graded patterns (digital preferred: DXF, PDF, AI)

- Fabric (rolled, not folded)

- Size breakdown (units per size)

- Trims (if bundling or kitting is requested)

- Any cutting instructions (e.g., direction of grain, nap, labeling)

We can send you a checklist to make this easy!